Most companies establish formal timelines with their clients before initiating new projects. Many find time overruns to be the most problematic scenario when executing projects plans. Not only do time overruns make clients question the capabilities of a firm, but they also lead to cost overruns.

They say that “time is money”. Time is rather the most important parameter as far as civil and mechanical engineering is concerned. 56% of companies find increasing pressure to bring products to market quicker than their competitors. With the application of CAD customization and design automation, engineers have the capacity to enhance their productivity and reap considerable time savings and expense reductions. Implementation of automation in the design phase has proven to cut delivery time with CAD customization substantially. Additional benefits include:

- Reduction in workforce, by reducing workload.

- Faster iterations with minimal corrections.

- Better collaboration across engineers, manufacturers, and clients.

Most companies establish formal timelines with their clients before initiating new projects. Many find time overruns to be the most problematic scenario when executing projects plans. Not only do time overruns make clients question the capabilities of a firm, but they also lead to cost overruns.

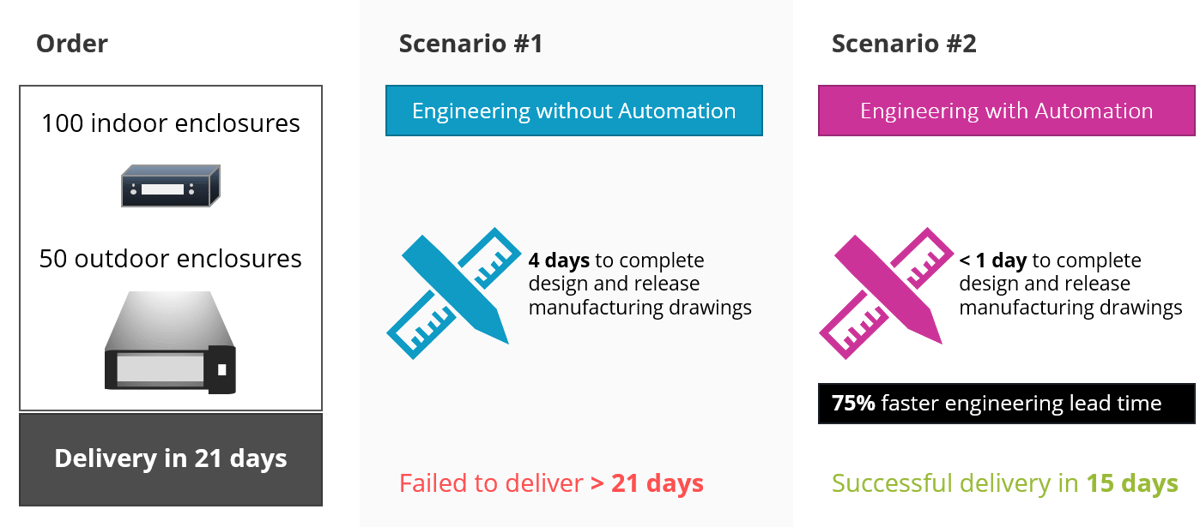

Scenario #1: Engineering without Automation

Let us take the example of a typical manufacturing company. The company is concerned with the manufacturing of sheet metal enclosures and employs a large number of skilled workers to manage its deliveries. The company specializes in custom enclosures, so most of its products are made to order. It receives an order for 100 indoor enclosures and 50 outdoor enclosures which are both of different sizes and types. The 150 enclosures are to be delivered in 21 days. Prior experience indicates that the company is capable of delivering 150 enclosures in at least 21 days. The company tries to deliver the order within the designated time period but fails to do so.

Slowdowns from manual processes followed by the time taken to produce the manufacturing drawings is the cause of the failure. On average, the engineering team’s lead time for a typical enclosure is two days. Since this specific order was for two different types of products, the team took twice the amount of time (four days) to complete the design and release the drawings for manufacturing. This delay cascades to other processes; therefore, is the reason why the company failed to deliver the order within the agreed timeline.

(illustration with and without CAD customization and design automation)

Scenario #2: Engineering with Automation

Another manufacturing company receives the same order for 150 enclosures as described in scenario #1. The company takes a knowledge-based engineering (KBE) approach to CAD customization and design automation. It takes the order, generates the manufacturing information (i.e. drawings, CNC codes, process sheets, etc.) in a few hours, and sends the files to the manufacturing division. Only one engineer is used to supervise the information generation process and has more involvement in the final stages to check the quality of the generated files. This company delivers the order within 15 days, which a company operating manually was unable to do in 21 days. Therefore, it is clear that the implementation of the CAD customization and design automation techniques lead to a considerable reduction in the processing time, as well as prevents any potential time and consequential cost overruns.

Takeaways

There is no second thought about the fact that CAD customization & design automation drives an efficient manufacturing process to meet the growing demand for product realization. Apart from reduced time consumption, there are subsequent efficiency gains with CAD customization and design automation adoption:

- The use of these techniques allows skilled workforce to be used in a strategic manner.

- Generating design alternatives through automation can reduce design errors by 80%.

- CAD customization has proven to shorten design cycles by 60%.

The adoption of CAD customization and design automation leads to reduction in design times and better manufacturing. As companies continue to evolve from using a conventional CAD approach, they will experience financial gains and increased efficiency.

About RGBSI

At RGBSI, we deliver business solutions that close the gap between strategy and execution for global organizations of all sizes. Our portfolio of solutions spans across the verticals of workforce management, engineering, quality lifecycle management (QLM), and information technology (IT).

With a strong engineering and IT backing, we work with global clients to customize CAD software in accordance to their business requirements. Our CAD customization and automation services include design process automation, drafting automation, macros development, API, toolbar, and user interface customization.

Learn more about our engineering services.