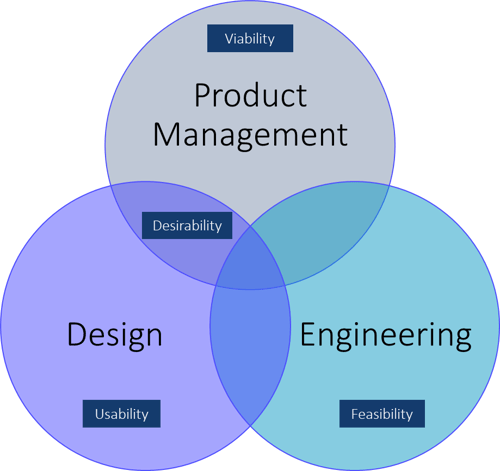

In product development, it is important for team members to have respect for each other’s skills. For example, designers must understand the technical considerations from an engineering perspective, engineers must understand why visual elements add value to overall product quality, and product managers must convey key attributes to enhance customer use experience. Addressing overlap through collaborative partnership among teams is what makes a successful product design team.

Mutual Understanding

Collaboration between design, engineering, and product teams is imperative for all parties have a clear mutual understanding of the end goal. Product managers, engineers, and designers need to have regular communication throughout the product lifecycle to establish a strategy, clarify the scope of work, validate solutions, and mitigate risks. When engineers understand the rationale behind product decisions, it drives innovations to come up with versatile solutions. Design iterations are reduced when designers understand the requirements of a product. Making better design decisions will be easier if all teams have a high-level knowledge of how the product is being put together. Using technology tools such as the digital thread can expediate the entire product design & development process in manufacturing.

Emphasis on Design Details

Design teams must convey important design elements to engineering and product teams so these intricacies are built into the product. For example, visual design elements such as color are important to designers but not a priority for engineers. Designers must explain why an element needs to look this way and the value it provides to the overall product quality. Using design automation can help combine multiple engineering concepts with real-life application.

Don't Sweat the Small Stuff

Designers are known for being meticulous when it comes to design perfection. Details are obviously critical, but one should not lose sight of the big picture. Prioritizing project details is valuable. Design elements need to be thought of carefully with their impact on overall product value and the number of people needed to incorporate them. Is this something necessary and beneficial to all or is this just a personal desire? It is important to let function inform design.

Put Your Guess to the Test

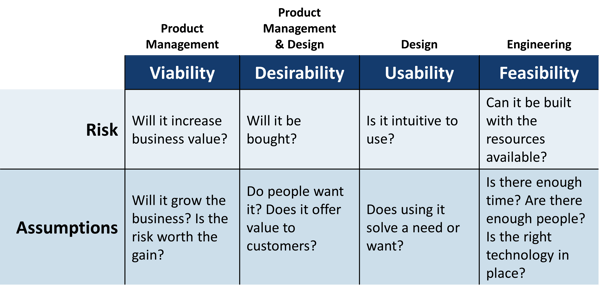

Nobody wants to spend time designing a product that has no want or need. Running experiments is a helpful gauge to put a design to the real test and learn about consumer behavior. It is apparent to test functionality, but what about desirability? Designers can make guesses on consumer taste and preference but putting these assumptions to the test can help solidify true desirability. Running desirability experiments early in the design process validates customer acceptance and can help avoid design flops. Completing comprehensive experiments across the 4 types of risk and assumptions will set the product up for success, avoiding surprises.

Team Alignment with the 4 Types of Risk & Assumptions

4 Types of Risk & Assumptions

Viability- Risk - Will it increase business value?

- Assumptions - Will it grow the business? Is the risk worth the gain?

Desirability

- Risk - will it be bought?

- Assumptions - Do people want it? Does it offer value to customers?

Usability

- Risk - Is it intuitive to use?

- Assumptions - Does using it solve a need or want? Is it usable?

Feasibility

- Risk - Can it be built with the resources available?

- Assumptions - Is there enough time? Are there enough people? Is the right technology in place?

About RGBSI

At RGBSI, we deliver total workforce management, engineering, quality lifecycle management, and IT solutions that provide strategic partnership for organizations of all sizes.

Product Design & Development Services

We supplement our clients’ core design teams with 2D & 3D modeling, CAD customization & design automation, CAD conversions, animation, reverse engineering, concept sketch proposals, and embedded system services.

Learn more about our engineering services.

Electrical & Electronic Services

We offer state-of-the-art services that fully integrate electrical and electronic design through manufacturing. With a “think forward” outlook, clients’ use our team of experts to ensure their products, systems, and processes are always current and compliant in the most efficient way possible.

Learn more about electrical & electronic services

.png?width=60&name=Struggling%20with%20EV%20Development%20Key%20Engineering%20Challenges%20and%20Solutions%20(1).png)

.png?width=60&name=Your%20How%20Digital%20Engineering%20Reduces%20Product%20Development%20Time%20by%2040%25%20text%20(1).png)