Definition of Measurement Statistical Analysis (MSA)

Measurement statistical analysis (MSA) is the practice of using statistical tools such as a gage R&R (repeatability and reproducibility) study to determine if a measurement system is capable of precise measurement. In addition, MSA determines the amount of error derived from the measurement process itself.

The purpose of MSA is to assure that a selected measurement system delivers reliable results with repeatability and reproducibility. When conducting a PPAP, all measurement systems are identified in the control plan. A gage R&R is performed for each one of these systems to check for precision.

Why perform an MSA?

MSA establishes confidence in data collection methods to verify the integrity of captured data used in other quality studies. This process includes evaluating measurement instruments, test methods, and data collection techniques. MSA helps manufacturers make informed decisions about their production processes and products. AIAG considers MSA as a core tool in improving the quality of decisions made through improving the quality of data used.

Identify Measurement System Errors

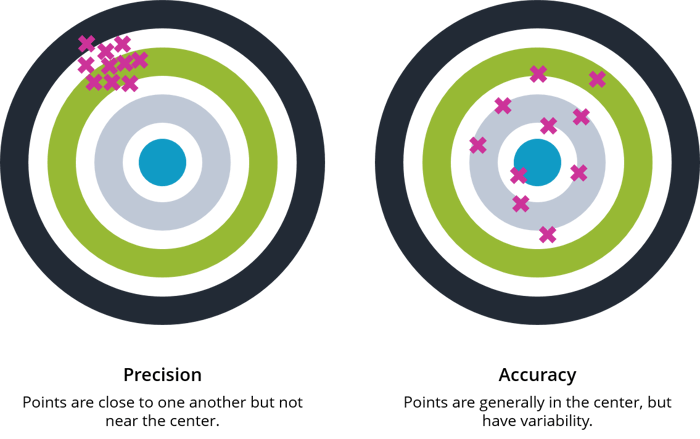

When conducting an MSA, data can either be true to the correct value or have system errors. MSA identifies these measurement system errors, which are classified by precision and accuracy.

- Precision: the closeness of the sample data points to each other.

- Accuracy: the closeness of the sample data points to the target value.

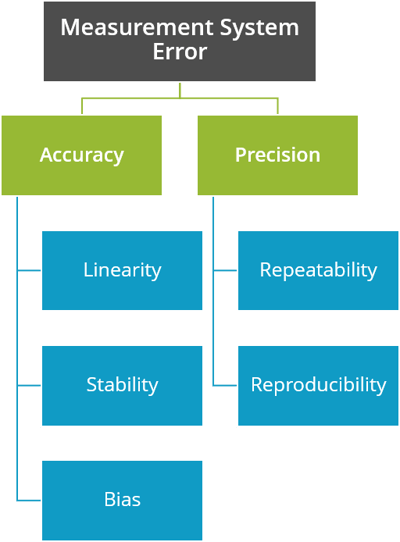

System Errors Classifications

A production control plan is applicable when a component is in full production. The plan is comprehensive of a characteristics, process controls, tests, and measurements conducted through full production.

Precision can be broken down into repeatability and reproducibility. A gage R&R study is used to estimate the combined measurement of repeatability and reproducibility.

Precision:

- Repeatability: the ability to get the same results each time the same measurement is repeated by the same operator. This provides information on equipment variability.

- Reproducibility: the ability of an operator to get the same results as that of another operator. This provide information on operator variability.

Further, accuracy can be broken down into linearity, stability, and bias. A gage linearity & bias study is used to determine if measurement instruments are taking measurements accurately.

Accuracy:

- Linearity: measures changes in accuracy of a measurement device through its range of operating capacity. For example, does accuracy change when measuring a component that is 5 lbs. vs 30 lbs.?

- Stability: measures the consistency in the practice of conducting the study over time. For example, is accuracy changing due to the operator using different techniques today vs one month ago to gather the sample?

- Bias: measures the differences that exist between the average of a sample data set and the actual value. For example, if a thermometer reads that it is 72 degrees outside when it is actually 70 degrees outside, the thermometer has a +2 degree bias as it reads higher than the actual weather.

Why is MSA important?

Having faulty measurement systems can cause poor quality components to slip through the cracks and high quality parts to be rejected. As a result, customers become dissatisfied with the manufacturer’s inability to meet their quality requirements. By conducting a MSA, manufacturers can make certain that their measurement equipment and operation of this equipment aligns with their precision and accuracy requirements.

About RGBSI

At RGBSI, we deliver business solutions that close the gap between strategy and execution for global organizations of all sizes. Our portfolio of solutions spans across the verticals of workforce management, engineering, quality lifecycle management (QLM), and information technology (IT). Through strategic partnerships, we help clients enhance performance, adopt innovation, and access global resources.

About RGBSI QLM Solutions

Need help with MSA, PPAP, or other quality areas? At RGBSI, we provide full service quality lifecycle management (QLM) solutions that optimize manufacturing supply chain initiatives. Organizations within automotive, aerospace, and other engineering segments leverage our expertise to validate, manage, and assess their current processes.

Need help with your quality lifecycle management activities? Inquire.